CRATEX Tools For Knife Making - CRATEX Abrasives

This article is part of Art of Knife Making series.

For full article click here

CRATEX is the leading US manufacturer of rubber abrasives. Many products from CRATEX assortment found use in knifemaking. Rubber abrasive wheels, cones and points are an inevitable part of knifemaking supplies. Rubber abrasives are especially convenient in the finishing process: for fine grinding and blade polishing, although many knife makers use them for handle finishing as well.

CRATEX abrasives are capable of: removing rust from old blades, initial blade deburring, removing scratches on blades, cleaning up and smoothing solder joints between guard and blade, cleaning plunge lines, blade polishing, knife engine turning – jeweling, all kinds of blade smoothing and rounding, blade mirror polishing, etc.

Grit Grades & Colors

When it comes to grit texture, all CRATEX rubber abrasives are divided into 4 groups:

- COARSE (C) - Green - 46 grit,

- MEDIUM (M) - Dark Brown - 90 grit,

- FINE (F) - Reddish Brown - 120 grit,

- EXTRA FINE (XF) - Gray Green - 240 grit.

1. Polishing Points

For polishing knife's hard-to-reach areas, you’ll need CRATEX points. Choose between three shapes depending on your work scope: bullet point, cylinder and tapered.

If you have a blade with grooves that need to be polished, or guard corners that must be smoothen, spirals on handles that need micro-deburring, look no further! CRATEX rubber points will get into places the sandpaper can’t. CRATEX Points are real time-savers for many knifemakers.

Depending on a blade size, choose a pin length and a diameter. Attach them to your favorite power tool, Dremel, CRATEX Rotary tool or a Foredom and get into every groove. Pins are flexible and can be re-shaped to suit the needs, so you can polish the file work on a knife blade in a few minutes. Depending on the shape, length, diameter and arbor hole, there are eight pin combinations. Along with the polishing point, you can order rotary tool mandrels in two dimensions. Get full info and order polishing points here.

CRATEX rubber polishers are imbedded with the silicon carbide, so they won’t heat up the steel, and you won't need to use anything to cool it down while working. Use them dry and forget about tripoli and rouge.

2. Small Polishing Wheels

Same as polishing points, small CRATEX wheels can be mounted on your rotary tool and used to cut and blend scratches, all in one operation. Small wheels are produced in 4 grit textures: coarse, medium, fine and extra fine. You can choose between two edge shapes: tapered and straight. Size from 3/8" to 1" and special cushioning can guarantee a smooth and soft metal removal without the loss of dimensional tolerances. Depending on the diameter, edge shape and thickness, you can order more than 10 wheels variations.

They offer a superior control over the knife blade and will ease your job when polishing knife edges and flat surfaces. Small rubber wheels are used by many knife makers since they are softer than other types of bonded abrasives. This means that even hobby knife makers can use them without the fear of grinding too much of the knife material.

Visit this page and see small wheels detailed specification.

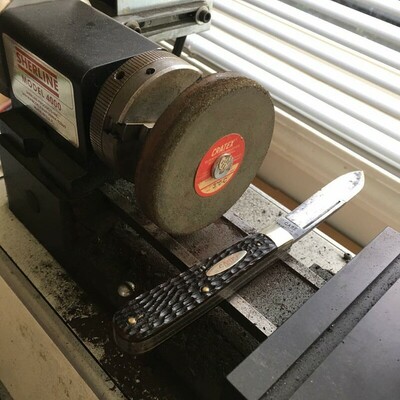

3. Large Polishing Wheels

For removing and leaning corrosion from long and tick blades, removing heat-treating marks on blades, smoothing swords edges, blade restoration, fine grinding after stock removal or sharpening other knifemaking tools in your shop, there are CRATEX large wheels.

They can be used on all conventional electric motors and bench grinders. Large wheels come in 1"-1/2", 2", 3", 5" and 6" size depending on the thickness and arbor hole. All CRATEX grits are available.

To check the prices and detailed specifications, visit Large Wheel page.

4. Polishing Rods & Sticks

The easiest way to make your knife unique and is to add fine patterns to a knife steel. Knife engine turning has been one of the favorite decoration technique for centuries. CRATEX polishing rods are the perfect solution for knife engine turning if you have a small drill mill. To learn more about length and cross-section on this link.

Watch the video below to see CRATEX polishing sticks in action. Video credit: @glennarehovinknives