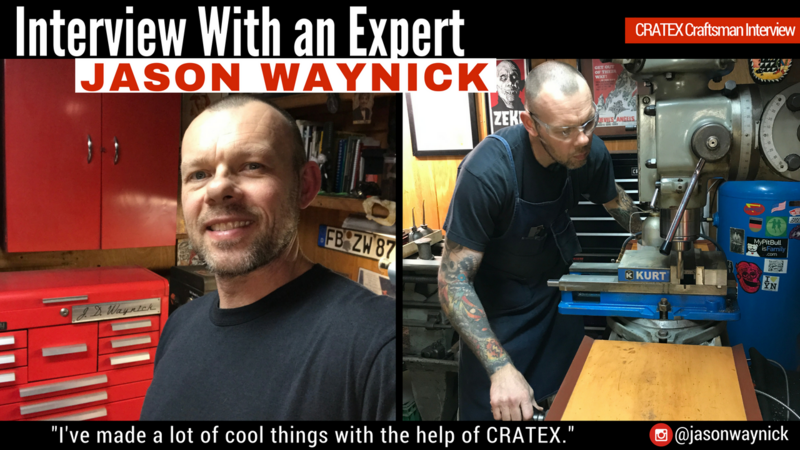

This week we had the pleasure to talk with Jason Waynick, who is an amazing machinist, welder, blacksmith and jeweler (among other things) from Nashville. Enjoy the interview and follow Jason on Instagram in case you like his work (and we know that you will!).

Welcome, Jason! And thanks for accepting to do this interview with us. Could you please introduce yourself to our readers?

-I am a craftsman from Nashville, Tennessee. I mainly work with metal and occasionally wood, plastic, paper, or whatever else needs customizing.

My daytime work is designing industrial automation equipment. My evenings and weekends are spent working in my machining and metal fabrication business.

Tennessee, Tennessee. Ain't no place that I'd rather be. Bicycle license plate that I made for a friend's child. #CNC #instamachinist #valerie #aluminum #bicycle #engineturning #WERKSTATT #cratexsandiego

How long have you been a craftsman and how did you become one? Who was your biggest influence?

-I have been building things and tinkering as long as I can remember. I built my first car a 1970 VW Karmann Ghia in my teenage years. I was in all the good high school shop classes.

My grandfather is my biggest influence in building things (and life in general). He had a killer shop and he was seemed like a wizard to me.

Do you mostly create pieces for you and your friends or you sell them as well?

-Gifts for family and friends, home items, and paying gigs as well. I have always been able to make cooler things than I could afford to buy, so I always have something in the queue.

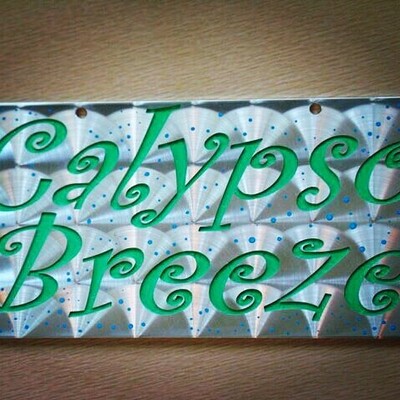

Sign for my bestie's toolbox. #CNC #instamachinist #engineturning #cratex #cratexsandiego #machining #WERKSTATT #cratexsandiego

Can you describe a day on the job as a craftsman? Or your typical work week if more suitable?

-My shop time is usually later in the evening. I enjoy being alone in the shop after everyone is asleep. It's my most productive time but can pose some problems when I'm running power tools in the driveway at midnight.

What are the projects that you are working on the most?

-Most of my jobs are general machine work and welding, prototyping, and a bit of blacksmithing. I have built motorcycles, prototype aerial surveillance cameras, fences, gates, mailboxes, sculptures, and jewelry. I built a "flying" machine for the Red Bull Flugtag with some friends last year.

Myself and some of my colleagues are building a craft for this event. This Saturday at Riverfront Park in Nashville. Putting the finishing touches on our flying machine today. Come watch us make history. #flugtag #flugtag2017 #flugtagnashville #WERKSTATT

How long have you been working as a craftsman and how did you become so interested in jeweling/engine turning in the first place?

-I started getting really serious about metalworking around 15 years ago when I landed my first real machine shop apprenticeship.

I have always seen engine turning on hot rods, guns, and old machinery and just loved the look and the tricks it plays on your eyes. I first learned to jewel metal with valve lapping compound and a wooden dowel.

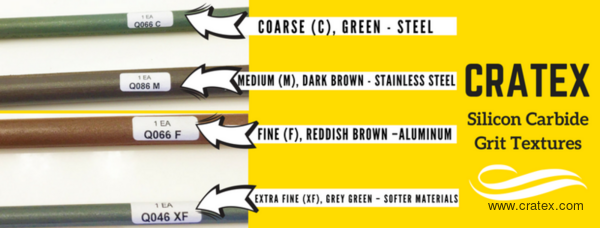

An experienced machinist saw me doing it one day and taught me about CRATEX sticks and I was hooked immediately.

What's the last jeweling project that you did that was especially challenging and you are proud of?

-One of my favorite projects with engine turning is a large wrench that I machined, painted, and engine turned with my name. The name was machined and painted before the engine turning, so the rubber bonded sticks required a lot of dressing as they contacted the machined letters.

I had been machining lots of nameplates for friends’ desks, so I had to make something killer for my own shop "desk".

Can you describe the way you’re doing jeweling step by step?

-I prefer to use a milling machine with digital readouts if possible. I usually run the spindle around 900 rpm's and apply pressure (similar to drilling) just enough that I don't flare the rubber out too much.

I will lubricate with cutting oil or WD-40 depending on what type of metal I'm working. I dress the end of my CRATEX stick with fine sandpaper every four of five turns to keep a nib from forming in the center and to keep the edges crisp.

Consistency of pattern is key for a great look. I will calculate the spacing that I want based on the size of the object and start turning.

Is there anything one must pay special attention to while jeweling/engine turning?

-Wipe the part frequently and check to make sure you didn't miss a turn or get your spacing out of whack. I check at the end of every row to make sure that I didn't make a mistake.

I also like to have a highly polished piece before I start turning.

I traded this sign for a week in a Florida beach house. CNC milled letters .125" deep. Engine Turned and hand painted. #machining #metalart #cnc #oneshot #aluminum #engineturning #americanmade #beach #cratexsandiego

If a mistake has been made while jeweling metal, is there a way to correct it?

-If your spacing gets off it will be the first thing that anybody sees. Your spacing has to be consistent. If you make a mistake it hurts a lot less if you only have to go back to the beginning of the row and not having to redo half of the piece. I speak from experience on this! Check your pattern often.

What type of metal do you work with the most?

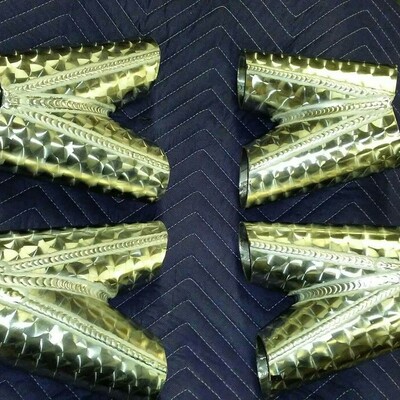

-Aluminum is my favorite, but I have turned Carbon Steel, Brass, Copper, Stainless, and Titanium.

What is the most uncommon item you’ve jeweled?

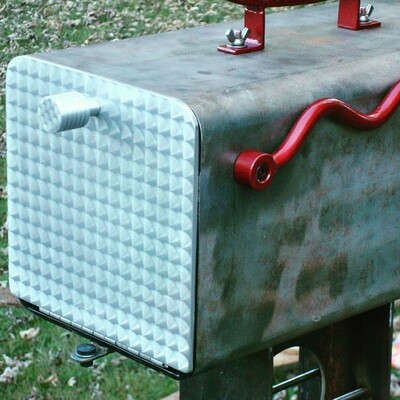

-Stainless knife blades, mailbox doors, or my brass Zippo.

I put a little flair on my lighter. Pretty sure it's going to work better because of it. #engineturned #engineturning #brass #camel #firestarter #dasprojektstahl #werkstatt #nashville #instamachinist @cratexsandiego

My mailbox before the patina set in. Full custom living. #werkstatt #metal #metalart #craftsman #steel #aluminum #engineturning #welding #cratexsandiego

I had a lot of fun building this one. Thanks to @enameltattooz for the killer pinstriping. #WERKSTATT #mailbox #kustomkulture #steel #aluminum #american #welding #instamachinist #engineturning #dasProjektStahl

What is your advice for those who are interested in jeweling?

-Engine turning is easy to learn. You can have something cool looking the very first time that you try. The more patient you are and the better materials that you use going in the better results that you will get.

There are plenty of tutorials online. I have found inspiration from the classic cars, airplanes, and machines from the early 20th century.

Take your time, it's always better to get it right than to do it fast. Once you get the hang of it you can really fly through it.

What are the essential tools you need for jeweling?

-A drill chuck or collet to hold the CRATEX, a good platform to hold your workpiece, some lubricant, and an abrasive for dressing the stick.

If possible, I prefer a collet to a drill chuck, because it doesn't squish the rubber, and I mostly use Fine grit sticks in 1/2", 3/4", and 1" round sizes.

Do you use other type of abrasives or just rubberized one?

-I have made homemade engine turning abrasives with Scotchbrite and elevator bolts. I made some large mandrels with 4 1/2" rubber backed grinder discs for some big special projects.

Besides abrasive rods, what CRATEX abrasives do you use the most?

-I occasionally use CRATEX mandrel mounted cones, points, and wheels with some of my jewelry making or small parts polishing.

What would be a good starter jeweling/engine tuning kit?

-I would start with an assortment of round sizes. The Mini Stick Kit 128S is a great starting point to try the different grits.

Why did you choose our products instead of some other manufacturer?

-I have never needed to look for another manufacturer. CRATEX is the industry leader for a reason. Quality and material are what I like the most.

Would you recommend CRATEX products and if yes, how would the recommendation sound?

-Yes! Output =Input. Choose quality products to work with and it just makes everything so much easier.