How to Jewel Metal | CRATEX Abrasives

This article is part of what is jeweling? series.

For full article click here

To show you just how easy this procedure is, we’ll explain metal jeweling with a CRATEX stick & a dill press in three quick steps!

Step 1: Polish your metal piece to a high shine

Many of people think jeweling is a good way to cover imperfections on a metal piece, and it is true – it can cover them to a certain extent, but don’t rely on it completely. If you have an uneven, rusty, corroded or scratched surface, the irregularities will still be visible which will take away from the beauty of your piece. Therefore, it’s essential to get your part mirror polished as only then will your swirls come to life. Depending on the condition of your piece, you’ll need to perhaps grind the surface off first, and then use a sandpaper or abrasive polishing wheels to achieve a mirror finish. The smoother the surface, the better your design will look. Don’t use a coarse sanding tool or a file, as those will leave deep scratches, which will be visible through your swirl pattern. The polished parts need to be oil, buffing wax or grease-free as well, so make sure you achieve a smooth and shiny surface before you start.

Recommended: CRATEX offers a wide variety of different rubber abrasive polishing wheels: small wheels with tapered and straight edges with 1", 3/8", 5/8", 7/8" diameters, and large wheels made in diameters ranging from 1"-1/2" to 6". Small wheels are available as a part of different sanding and polishing kits, including a small kit for testing different grits out.

Step 2: Set up a jig or vice for a drill press

First, you must cut the abrasive stick into 1 1/2"-2" and stick it into the drill chuck. Make sure only about 1" should sticks out, because larger pieces flex easily and reduce precision. If you’re using CRATEX rods, no abrasive compound is necessary, so you can apply the spinning rod to a polished surface without it. Of course, you CAN use some depending on the finish you would like to achieve.

Before you jewel, make sure you practice on some stuff you don’t care about first, a piece of scrap metal, because you probably won’t produce a pattern you like or are satisfied with. It takes time to get the feel of how long you should hold the tool in contact with the surface and how much pressure to apply.

Use paper towels or cloth on a vise in case you are using an abrasive compound to avoid getting the compound all over your tools and workspace.

Next, you’ll place your workpiece in a covered vise or a table that is located beneath the drill bit. Be cautious when applying the abrasive compound because you don’t want to put any additional scratches onto your workpiece. One way to apply a compound, especially the nasty stuff, is to use a toothpick or a cotton bud.

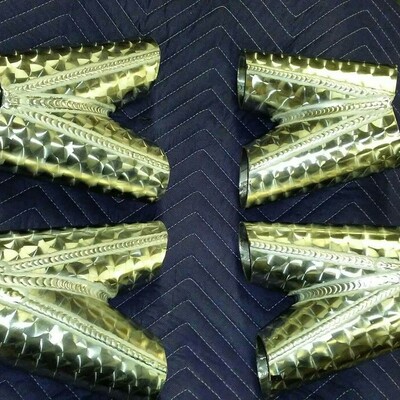

Step 3: Create small, overlapping circles in the polished metal

Important is to come up with a way to create straight lines and keep the swirls indexed at same spacings since you’ll be using a drill press and not CNC milling machine. To gain more accuracy, particularly when handling a large piece, you can clamp a straight-edge ruler with distance markings for creating more precise crossovers. Plan out the pattern, lower the drill press against the metal surface, hold for desired number of seconds, raise the press, move the piece to create an overlapping circle and repeat with the same pressure and for same amount of contact time. You should apply light pressure when using CRATEX abrasive sticks, as strong pressure is unnecessary, and it will damage the rod’s end. The goal is to create jewels that overlap with previous jewels, so that the “eye” of the previous jewel is visible, but not too much space is left between them. The best rotating speed to work with would be between 900 and 1400 rpm.

In case you used an oil-based compound, you’ll need to clean it off with something like a paint thinner first, and in case you used a water-based compound, you can rinse it off with water. Don’t wipe it all over the surface as you’ll scratch the surface. Then, gently polish the surface with a cloth afterwards, making sure you’re not applying unnecessary pressure as that could also damage the work. Finally, it would also be good to cover your piece with a clear protective finish.

A Word from the Professional

I use a CRATEX cylinder in a stainless-steel tube. The CRATEX is rubber impregnated with abrasive. The tube provides rigidity and as the CRATEX wears down I just advance more out.

The tube with the CRATEX then gets chucked up in the drill press.

Turning about 500-600 rpm just bring it down on the work piece, then move over half the diameter and do it again. Keep going and in a few minutes, you'll have some nicely jeweled parts.

I mostly use .250" diameter, but there are several to choose from. The .500" creates a nice effect, too."

- @kc_gray_knives Professional Knifemaker from Tucson, AZ