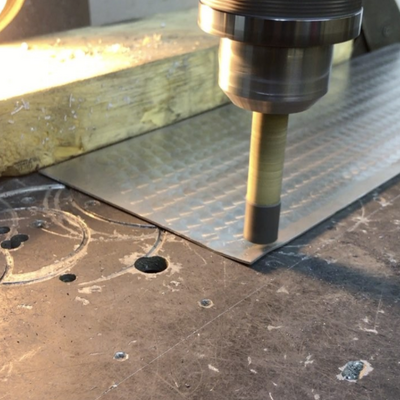

Engine turning flat sheet aluminum with a 1/2" diameter CRATEX med grit sanding rod. Its fun and can be done with a drill press or hand drill. #swirl #engineturning #jeweled #hotrod

Free UPS Ground shipping on all online orders over $149

Buy CRATEX sticks for engine turning at fantastic prices. Choose cross-section, grit texture and quantity and we process your order same day. FREE delivery for $149+ orders. Get proven quality from the most trusted US abrasive manufacturer – CRATEX.

What is Engine Turning?

Tools for Engine Turning

Engine Turning Abrasives

How to Engine Turn

Expert's Show & Tell - Jim Yocum Partner at Raleigh Speed Shop

CRATEX Engine Turning Customer Projects

Engine turning is a process of adding fine (decorative) patterns on a flat metal or steel surface as a finish. It brings a truly unique touch to a workpiece and gives it an almost holographic depth. And it’s not just for being pretty, it is also thought to make cleaning easier. Aluminum is the metal that is used most often, but, basically, any metal can be decorated with these repetitive, swirly patterns - stainless steel, nickel, gold, chrome, etc.

Traditionally, the term in English was used in jewelry and horological trade. In Francophone regions the synonym for engine turning is guilloche, patterned curved-line finish produced by the application of a single-point cutting tool (rose-engine, straight-line engine or decoration lathe). It is usually seen on fine, high-end horological work and exquisite jewelry design (e.g. contemporary watch engraving dominated by the Swiss, or the delicate work of Fabergé under the Russian Tsars).

Fine jewelers don’t like referring to engine turning as “jeweling”, since they consider the process too coarse for an Ornamental Turning that they deal with. Besides, guilloche patterns are patterned designs found on money, stock certificates and other valuable papers, with the main purpose to make counterfeit more difficult.

On the other hand, “spotting” was the term used for an abrasive finishing process. A rotating disc or a rotating dowel with an abrasive at the bottom would be pressed down to a metal surface, to create fine, overlapping swirls as the finish. “Spotting” became very popular at the beginning of the 20th century, and the most recognizable example is the decoration on the engine cowling (nose) of Charles Lindbergh's aircraft, which was a custom-built, single-seat monoplane, that took him on the first direct transatlantic flight from Long Island (NY) to Paris (FRA).

Later, during the 20s and 30s, people started decorating car parts like valve covers, instrument panels, and other engine-turned panels that were added as a part of customization. By the middle of the 20th century, engine turning has nearly disappeared as an industrial process, and the term “engine turning” began to be applied to “spotting”, mostly among automobile enthusiasts, so “engine turning” quickly became the new and legitimate term for decorative swirls created by pressing down abrasive sticks among automobile restoration community.

There are a few other terms often used interchangeably with “engine turning”, such as damascening, krayling, ornamental turning, swirling, snailing, mottling, however, there are limitations in appropriateness when it comes to applying it to different processes and work pieces. For example, the term “damascene” has been used in the jewelry and ornamental metalwork trade since the 16th century. Although we find the term “damascene” used for an abrasive finish since the 40s, “damascening” refers primarily to a two-metal finish, a process of inlaying two precious-metal wires into one another to produce intricate patterns, which is completely different from both “engine turning” and “spotting”. Besides that, there’s also the Damascus steel, which is something completely different. The term is used to describe a very specific “wavy” patterned sword blades that appeared in the West through trade from Damascus. The process of creating the wavy pattern includes a tool that this a shoulder brace and an angled, polished end.

So, each of the “synonyms” for engine turning should not be used ever so lightly. When it comes to putting an abrasive finish to a metal surface, although nowadays “engine turning” is often used interchangeably with “jewelling”, the term “engine turning” is primarily used for high-quality automotive metalworking – the ornamentation of classic cars and hot rods that creates a classic look of old-school craftsmanship (e.g. steering wheel decorations, valve cover, firewall, dash and console, glovebox, rear spring covers, switch panels, gas tank straps – you name it!) or motorcycles (e.g. gear case, instrument pod, tank, headlight, etc.) “Jeweling” refers more to the decorative touch on the different parts of firearms and knives, tools, instruments, and so on – all objects that can be made prettier and shinier, really. This is why we’ll discuss jeweling in a separate article, so make sure you check it out here.

The overlapping circles can be pressed into any metal by using different tools, and the choice depends on the type of metal (i.e. thickness) and work surface. In case you are working on large projects, you’ll need to use large brushes, and in case you’re working on smaller, more delicate projects, you’ll use smaller brushes or smaller abrasive bits that can be inserted into a drill press, hand drill or a Dremel.

Engine turning can be done with a lot of different tools, and it’s quite possible that you've tried most of them by now, unless you were fortunate enough to come across the perfect tool that gets the job done without much wandering and disappointment. Some use a wire brush or buff with an abrasive compound, such as Mag Wheel Polish. The swirls are made by the abrasive action of grinding compound and the brush provides pressure and motion. Brushes have their advantages on curved surfaces and sharp edges, but the problem is that some wires are longer than the others, so it they end up digging deeper into the metal, so your design might not get the smooth and shiny finish that you imagined. Besides that, since the wires tend to spread during the usage, a lot of craftsmen put rubber or hose clamps to achieve a tighter pattern, which is unnecessary work if you think about it.

When it comes to engine turning aluminum, for example, tools like sanding discs can also be used. However, you’ll end up spending a fortune on sanding paper, as they get worn out after three or four burnishes in a row. Sanding paper on elevator bolt is proven to be too hard, and it doesn’t conform to the flat sheet enough to produce uniform circular swirl. Double sided tape creates a pattern that is too faint, so you get ghosting on the overlaps. And if you apply too much pressure, the paper slides off. Some use hardwood dowels, and indeed, decent results can be reached. However, the problem with that is that you’ll constantly worry about adding compound – about every half of the row or so. An additional problem is that the compound would get too much after a while, the dowel would plunge and leave a dark ring on the next swirl.

And it is true – some people managed to get some decent work done by using a pencil eraser and a grinding compound (toothpaste even), but would you really want to do that?

A much more convenient and efficient option would be using two things, basically: a drill press and rubber abrasive stick of CRATEX. Just a little of any convenient lubricant would be welcome in case you are looking to create a bit deeper swirls. This option also requires patience and focus, but it is a quick and inexpensive way to put truly nice surface finish on your parts.

Working on the mill press is a bit easier, since you have an X, Y table and all you have to do is keep track of the distance when moving in a certain direction. Possibly the easiest option would be using a CNC machine. It shortens the engine turning process and thanks to the precision of the CADCAM software, a perfect layout can be achieved quite easily. Besides being more accurate in terms of creating a pattern, it is also more consistent with the pressure on eachswirl pattern.

Depending on the type of the machine, you can set parameters, like the speed RPM, tool diameter, dwell at depth, tool number, clearance removing, Z feed rate and Z depth, the direction of the pattern and so on and generate a code. The machine’s normal coolant is quite enough, and you can turn it on or off if you like, and there is no need for adding oil. But of course, you can add an abrasive compound in case you want to achieve deeper marks.

So, lapping compound is something you’re most probably going to use at some point. It’s a mixture of hard abrasive particles and lubricants which can be either oil-based or water-soluble. The way the compound works is that the abrasives increase the rubbing while the oil tends to reduce and control it. There are different lapping abrasives with different grit numbers that can be used for different types of metals, so important is to find the one most suitable for your work.

A very light mist of 25 parts of water to 1 part of oil mixture (any oil from cooking to motor) is highly desirable for best results. The compound helps avoid metal discoloration and deterioration of the abrasive stick, so recommendation would be to use it after every spin. Of course, as mentioned previously, it is possible to do engine turning by using only a drill press and abrasive sticks, but different abrasive compounds (90, 120, 220 grits, etc.) to achieve deeper or better-looking swirls can be used in the process (the higher the grit rating, the finer is the paste).

The thicker compound, e.g. the 90-grit, is great for any job, as it can be mixed down with lubricants, and made thinner if necessary. On the other hand, thinner compounds, like the 120 or 220-grit, cannot be made thicker. One must be careful when adding additional lubricants as more lubricant means that the effort and cutting action of the abrasive particles is reduced and they can easily get washed away in case too much lubricant is added.

The compound can be applied with a toothpick or similar on smaller pieces and you’ll need to be careful not to get your vise or drill press dirty, as abrasive compounds are quite messy and a lot of them tend to fly all over the place. Make sure you cover and protect your tools before you start applying and be careful when taking the compound off the piece after you are done as there is a risk of damaging your work by wiping. Use a soft tissue, toothpick, clean the surface with compressed air, wash it off with a suitable solvent or water and detergent stream, or paint thinner.

CRATEX abrasive manufacturer from California US offers a wide range of 6 inches length sticks perfect for engine turning available in following diameters 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 7/8” and 1” and the choice depends on the and the desired diameter of the spin.

Depending on the kind of metal that engine turning is applied on you’ll need to choose appropriate stick grit. CRATEX rubberized sticks are made in four grit textures:

1. Coarse (C) - steel

2. Medium (M) – for stainless steel

3. Fine (F) – for aluminum

4. Extra fine (XF) – aluminum and other softer materials.

Sticks are rubber bonded and made of purest silicon carbide. See below grit colors.

The appropriate grit depends on the type of the material that you’re working on, and it’s important to choose the right one that could cut enough to eliminate the previous swirl (i.e. that could avoid ghosting). For example, we can recommend the medium grit for aluminum, and coarse grit for stainless or other types of steel.

1/2" Cratex stick - Medium grit - it gives pretty good coverage with minimal ghosting. Long lengths in the press "wobble" too much. I will need to make a mandrel to hold short pieces. Chucked a short scrap in the press and got OK results from it, tried some WD40 for lube since it was the first thing in the flammable cabinet and the swirls came out VERY uniform and clean!

My verdict? I am going to order some 1/2" and 1" Cratex for the various parts I need to do. I am VERY HAPPY with the results! - Tman, SD

CRATEX engine turning abrasives can be bought in bulk, and as a single stick as well. In case you are looking for an engine turning kit, we highly recommend Mini Kit 128S for trying out different grits. Shipping and handling are included in the unbelievable price offer and the kit includes one stick for every grit.

@nemomatic Thanks to the miracle of time lapse video, you can experience what was an incredibly long and grueling studio day in just one minute. "Engine turning" sheet metal, I've learned, is something you shouldn't do. It's a drag. But I'm pleased with how my home made drill press rig worked out. The effect is really cool, and you don't usually see it on such large panels (now I know why). I still have to do the other panel, but it'll have to wait for my old bones to stop aching first.

@_craftyb_ Kirk Brown owner of Crafty B Nostalgic Speed, builder of the worlds coolest gas caps.

I use a Cratex rubberized abrasive stick in a drill chuck on a Bridgeport. Just go down to surface, let it dwell, then step over a couple of handle turns (about .400")

The Cratex is a standard deburring thing if you’re not familiar. It looks like a long pencil eraser and it is rubber with abrasive stuff molded in it. Some have used a wood dowel with valve lapping compound on the end the same way. - WA Toolman

This chapter is going to deliver some Engine Turning 101 – main steps to follow and some basic instructions and points you should consider. You’re going to need: a metal sheet, pencil and a ruler, CRATEX abrasive rods, drill press and some protective gear.

One of the first and most important things to remember is to always wear eye protection and never permit anyone to view the operation without the proper eye protection. Since you’re going to be working with a drill press, it is a good idea to protect your hands with from sharp metal edges with safety gloves. Be careful particularly when using tools abrasive pads on steel as powdered metal will get blown directly into your face. Unless you want to spend days blowing gray from your nose into tissues, we suggest you wear a mask.

After you get geared up, you’ll need to clean the work surface. The surface needs to be completely clean, polished and flat. The best results will be obtained if engine turning is conducted on a flat piece of metal, so in case you need to work on a curved piece, make sure to flatten it for applying decoration and then simply reshape it after you’re done.

Depending on the project, you’ll need to mill or grind the surface off first, or just use a sand paper or hand rotary tool with fine abrasives to smooth down the surface and remove any imperfections that would show through engine turning and ruin the finish. It is a misconception that the patterns will hide all irregularities on the surface of your project, and make sure you don’t use a file or coarse sanding paper to polish the surface, because those could leave deeper scratches which will also show through the swirl and will ruin the design. Important lesson here is: the smoother the surface, the better the engine turning pattern will look.

You can clean the surface with alcohol after you’re done to remove any fragments occurred during the process.

The next step would be to mark out the lines for engine turning (some even use digital readouts and spreadsheets of X and Y positions for supreme accuracy). First, you should measure the width of your piece and draw lines to guide you through the process. You can start with the center line drawn with the help of a 90-degree ruler. Next, you’ll measure the rubber abrasive diameter and determine the degree of overlaps. Now grab a ruler and start drawing lines parallel to the center line based on the determined overlap spacings (you can mark the spacings with small hash lines both horizontally and vertically). In the end, you should get a net with identical square fields and the rod should be pressed down on each cross.

You can also use a tape or a lead pencil, just make sure you never use a permanent marker or sharp objects to scribe the working surface for guidance.

CRATEX sticks should be cut into 1-1/2 to 2” parts and placed into the drill press chuck with about 1” part or less exposed as it will provide the best precision. The longer the exposed part, the greater the chance of developing a wiping type action that will result in larger spins, but the longer piece tends to flex more easily and that way you’ll lose accuracy.

Always be careful not to over tighten the abrasive stick after placing it in the rotating device as it will eventually snap off if tighten too tightly. The best rotating speed is between 900 and 1400 rpm, but it’s best to start slower and then adjust the speed as you’re getting the hang of it.

Important safety tip: Always make sure that your drill press is securely attached to a flat, stable surface.

After completing the machine preparation, the next step would be to execute initial testing on a scrap piece of metal until the desired spin depth is achieved. You should also experiment with the lapping compound on a scrap metal first before using it on real workpiece.

To determine the spin depth also means to determine the desired cycle time or the time the rotating abrasive stick is supposed to be pressed down on the surface and the pressure. After a few tries, the same pressure and pressure time should be applied during every cycle. Pressure should be light as strong pressure will cause the end of the abrasive stick to roll out to mushroom and cause inconsistent patters sizes. Some use digital scale, which reliefs you from worrying about the pressure, while you’ll still need to be focused on the contact point each time you’re about to apply pressure.

Precision is not that important here, especially when starting out, but uniformity of spacing is crucial. Consistency is what will contribute to the professional look of the design. Correct pressure will prevent you from destroying your piece of work, so give yourself some time. Note that a very light pressure is needed when using CRATEX rods on a drill press, and the slower the speed, the less compound you get flying all over the place.

Typically, the overlap of the swirly decoration is done by half the diameter of the abrasive, but that is now a strict rule – so 1/2, 1/3 or 1/4 the size of the swirl – it’s up to you. The circles can overlap more or less and can be pressed in straight lines or at an angle. Some machinists have their own way of pressing the decorations, which eventually becomes their signature. Moreover, many old-school craftsmen prefer working on a drill press, as their goal is to achieve a more hand-made look and a less CNC look and despite drill-press work being a lot more physically intense, especially when you’re working on larger pieces, like firewalls.

After you’re done, apply a clear coat to strengthen the abrasion resistance.

From time to time CRATEX abrasive stick may become embedded with metal particles and will need to be dressed back to expose fresh abrasive. Standard CRATEX dressing block or a fine grit sand paper can be used for this purpose, just make sure very light pressure is applied for a few seconds against the dressing material.

For our Expert's Show & Tell this time, we had the pleasure to talk to Jim Yocum, a Hot Rod and Race Car builder and the partner at Raleigh Speed Shop , an automotive fabrication shop in Raleigh, NC that specializes in race car fabrication, sheet metal shaping, precision welding and machining. Jim has more than 20 years of experience with race car fabrication and custom car metal work and he's an expert in TIG and MIG welding, machining, sheet metal work and metal shaping. His shop is also the proud Raleigh-Durham area JRI Shock dealer.

Jim had an interesting project going on recently for one of his clients and was kind enough to share a part of it with us. He decided to engine turn the radiator bracket on a 1967 Pontiac GTO which is one of the last models that marked the era of muscle cars. It is certainly a definition of 1960s true American sports car and it belongs to a short period of time between the 1967 and 1969 when many would agree the most beautiful muscle cars ever were produced.

It wouldn't feel right to jump right to Jim's project without writing a few lines about the car that is often considered the first true muscle car. The muscle beauty and one of the '60s absolute favs came standard with a 400 cubic inch V-8 motor that delivered 335 horsepower. The letters GTO stand for "Gran Turismo Omologato" ("Grand Tourer Homologated"), so its name implied that the car was created with racing in mind and was eligible to take part in races such as the LeMans. Pontiac's marketing approach at that time was heavily based on performance and therefore, racing, so the name assigned to the car was a joint idea of General Motor's marketing agency executive and one-time Pontiac chief engineer, John DeLorean. DeLorean got his inspiration from the Ferrari 250 GTO, which was a highly successful and admired sportscar at that time. The move encountered protests by GT class followers, as the name suggested the car was meant to race in the GT class.

The body of 1967 GTO remained true to matchless lines of the 1966 model, so the biggest changes were mechanical ones. The body itself had a few changes such the side-trim change, chrome wire mesh on the grill which made it distinctive and new tail lights with some edges resculpted and the lamps cleaned up. And while it was considered a car with a heck lot of muscle, it was also considered one of the best looking mid-size cars of the 1960s. Three different body styles were produced: the two-door coupe (production total 7,029), the two-door convertible (9,517) and the two-door hardtop (65,176).

Now that we paid a short tribute to this gorgeous classic car, it's time for Jim to take the stage. This is his Expert's Show & Tell (and yeah, did we mentioned he used CRATEX rods in the process?)

The piece that I'm engine-turning is an aluminum radiator support bracket for a 1967 GTO. I polished the part prior to turning which helps make the panel a little brighter once turned.

I sanded the panels with a DA sander starting with 800 grit and worked my way to 2000 grit. I then used aluminum polishing compound and a buffer to polish the part.

This part was turned using a Milling Machine in order to achieve accurate lines and spacing. A drill press could be used as well with some additional layout and fixture work. For this piece I'm using a 3/4" CRATEX stick.

The layout will use .4" horizontal and vertical spacing, but any pattern you like can be used.

I like this spacing for the 3/4" stick because it leaves a little more than half of the pattern showing which still shows the center of the swirl. I start at the top left and complete each row moving horizontally.

Once the first row is complete I work down with each row starting .125" before the previous to give the pattern a slightly stepped look.

I use WD-40 to lubricate the panel prior to turning and after each pass a blow off the residue and oil before starting the next row.

I also periodically touch up the CRATEX stick bottom with some 120-grit sand paper on a sanding block to ensure the stick still has a smooth and even base for consistent markings.

Follow Jim on Instagram: @jamesyocum

Follow Raleigh Speed Shop on Instagram: @raleighspeedshop

@tjmhotrod I thought I would try Engine Turning. This is a nod to the old skool race cars and hot rods from a bygone era. #cratex #cratexsticks #hamb #hopupmagazine #hopuplive #earlyracing #vintageracing #hotrods #vintageinspired #vintageindustrial #metalwork #metalworking #engineturning #engineturned #metalworks #cratexsandiego #hotroddash

@402bossman Doing a little engine turning with some Cratex Sticks on my mill @cratexsandiego. Jamming out to some Buddy Guy trying to give this billet valley plate some character! #smithbergracing #earlyhemi #chryslerhemi #oneoff #custom #cratex #engineturning #fishscales #jeweling #adamsandsmithberg

@402bossman When your heads are going on a unique car and you need a detail to help stand out. Badass set of Mastodon Early Hemi heads finally near completion. Using some Cratex Sticks that I got from #cratexsandiego to do the engine turning on the ends of these heads. #tbt #throwbackthursday #smithbergracing #earlyhemi #oneoff #custom #aafuelcoupe #nostalgia #nitrofuelcoupe #tedbrine #jeweling #engineturning #fishscales #cratex #cratexsticks #cratextools #cratexabrasives #cratexrod #cratexmanufacturing #cratexproject

@jamesyocum - Working on a toolbox hutch for my box at work. These are Blum hinges that I thought would be cool. Next I will skin it with some .063 aluminum. #toolbox #hutch #blum