Jewelling

Products (1)

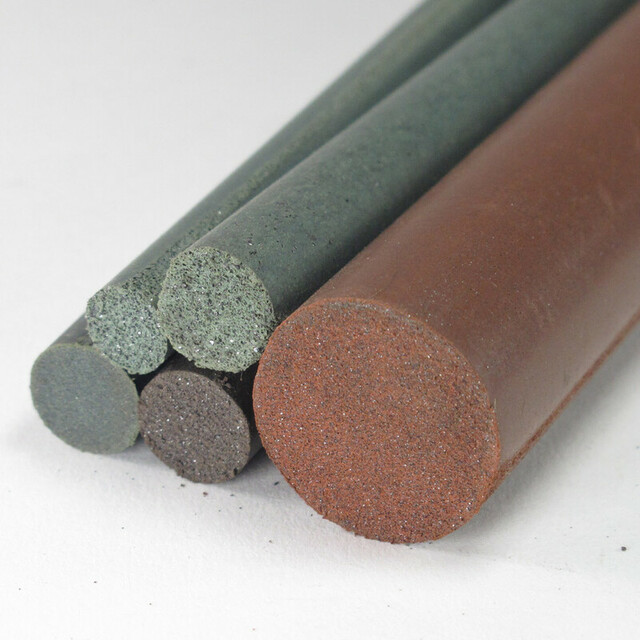

Round Sticks

Choose options

Stick diameters: the diameter of the stick determines the diameter of your spin, therefore select the appropriate stick diameter that you desire your spin to be.

Grit selection: Cratex jewelling rods are available in 4 different grit textures:

- Coarse (C)

- Medium (M)

- Fine (F)

- Extra Fine (XF)

Metal types: Using the application guide below chose which grit is best suited for your application.

- Stainless Steel (harden metals) – Medium or Fine.

- Aluminum (softer metals) – Fine or Extra Fine.

Instructions

Cratex sticks should be cut into 11/2” to 2” sections. Chuck the sticks into a drill press leaving only 1” or less exposed. The longer the exposed length the increased chance of developing a wiping type action, that will result in larger spins then desired.

Never over tighten the chuck when mounting the abrasive stick into the rotating devise (dill press or other machine) to avoid it from eventually snapping off. The best rotating speed is between 900 and 1400 rpm.

Lubricant: a very light mist of 25 water to 1 oil mixture is necessary. Any old from cooking to motor oil can be used in a spray bottle. Mist where the abrasive stick meets the metal to reduce any heat build up.

Spinning first experiment on a scrap piece of metal until the desire spin depth is achieved. When doing so determine the cycle time (how long the rotating abrasive stick is working against the metal). If that is 5seconds, then your cycle time is 5 seconds per spin.

Pressure: when developing the spin cycle time make note of the pressure applied. Use the same amount of pressure (which should be very light) for each spin.

Spin cycle time and pressure: you do not need to be precise to achieve a profession looking spin but try to be consistent.

Spin pattern: simply slid the metal work piece ½ distance as the spin diameter to achieve an over lap spin appearance. Follow this procedure until your metal work piece is complete.

Stick dressing: from time to time the jewelling rods may become embedded with metal particles. The stick will need to be dressed back to expose fresh abrasive. You can place a standard dressing block or a fine grit sand paper block on the work rest and bring the stick down onto the dressing material. Keep the rotating stick with very light pressure for a few seconds against the dressing material. The abrasive stick will wear away slightly and expose all fresh abrasive.

Warning: always wear eye protection; never permit anyone to view the operation without proper eye protection. Always use caution and care with any rotating abrasive product.